Both Corn Crackers feature special roller profiles, which allow highly intensive conditioning of silage with medium to long chop lengths of up to 30 millimetres. These systems are particularly useful to farm contractors, allowing them to respond even more flexibly to increased conditioning requirements for maize silage, and especially the trend towards longer chop lengths for dairy cow forage.

The new corn cracker systems integrate seamlessly with the existing CLAAS MULTI CROP CRACKER concept, which is particularly flexible due to its various roller profiles. A standard, easily accessible cracker housing allows the various rollers to be changed quickly and easily depending on the desired conditioning level. It is, of course, possible to place an ex-factory order directly for the MULTI CROP CRACKER.

The MCC CLASSIC standard cracker system with sawtooth profile in sizes M and L, which has proven its effectiveness over many years, will remain an integral part of the concept. This is particularly suitable for short cut silage from 3.5 to 12 millimetres, which are mainly used for biogas plants but also for dairy cow forage and bull fattening.

High conditioning quality for long-cut silage

The newly developed MCC MAX corn cracker system from CLAAS offers even more flexibility as it caters to the growing demand for long-cut silage. It has been developed for conditioning maize silage with chop lengths of between 7.0 and 22 millimetres and is characterised by special conditioning rollers featuring a sawtooth profile and 30 annular segments each. The positioning and special geometry of the annular segments ensures that the choppings are not only processed by friction, but also by cutting and shearing forces. This allows even more intensive conditioning of the grain kernels as well as shredding of the stalk material.

The crucial advantage of intensive conditioning is that, instead of the usual chop length of approx. 5.0 millimetres for biogas silage, longer maize cuts of 7.0 millimetres in length can also be used for biogas generation. This is because the high level of conditioning provides bacteria with a significantly larger surface area to act on and thus optimises the fermentation process.

The special conditioning quality of the MCC MAX also proves advantageous for long-cut silage, which is increasingly in demand from dairy producers. Here, the bacteria in the rumen of the cow also benefit from the significant increase in surface area of the material. The greater starch digestibility of the silage and improved structural suitability of the long chop have a positive effect on milk production and animal health.

The MCC MAX system thus offers the greatest possible flexibility. This is because only a corn cracker system allows the production of both high-quality short-cut silage for biogas plants and high-quality long-cut silage for dairy cow forage. It is not necessary to exchange the rollers because the chop length can be adjusted from within the cab through the cutting cylinder. The only important requirement is that the chop length range of the chosen cutting cylinder must be suitable for the MCC MAX system.

New technology from the USA

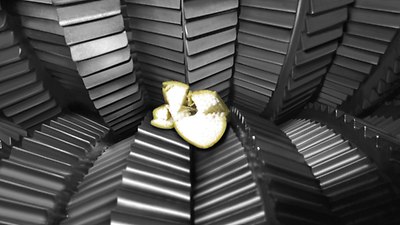

CLAAS has also introduced another new corn cracker roller, the MCC SHREDLAGE®, after acquiring a licence for its technology. This roller allows intensive conditioning in the extremely long chop length range from 26 to 30 millimetres. The SHREDLAGE® rollers feature a sawtooth profile with an additional counter-rotating spiral groove. This allows the MCC SHREDLAGE® to fully break down the cob pieces and crush the kernels to break them open completely. Furthermore, the stalk material is shredded very effectively in the longitudinal direction and the bark is peeled off by the special roller profile.

This technology was developed by the American company Shredlage L.L.C. Many dairy farmers in the USA and now also in Germany are already feeding SHREDLAGE® silage to their animals with great success. Initial studies by the University of Wisconsin, USA, have found that the very high level of starch availability from SHREDLAGE® can increase daily milk production by up to two litres per cow.

In future, CLAAS will manufacture SHREDLAGE® rollers itself on licence at CLAAS Industrietechnik in Paderborn. Like the MCC MAX, the MCC SHREDLAGE® will be available as an ex-factory option or for retrofitting from 2016 for the JAGUAR 870, 880* and 950 to 980 models.

*Only in North America